Please Choose Your Language

Tel: +86-131-8042-1118

E-mail:

E-mail:

26 Huanghai Road, Leting Economic Development Zone, Hebei Province, China

Views: 0 Author: Site Editor Publish Time: 2025-12-17 Origin: Site

Cuplock scaffolding system is one of the most widely used modular scaffolding system solutions in global construction, known for its versatility, safety, and rapid installation. It is engineered with a unique cup-and-blade locking mechanism that allows workers to assemble large structures with minimal effort and maximum stability. Over the past decades, cuplock scaffolding has become essential in infrastructure, industrial plants, residential buildings, bridges, and large-scale formwork support systems.

As construction projects continue to prioritize efficiency, load capacity, and worker safety, the cuplock scaffolding system has proven to be a reliable, cost-effective, and durable option, suitable for both temporary and long-term applications. Whether used as façade scaffolding, shoring platforms, access scaffolding, or heavy-duty support towers, cuplock systems ensure structural integrity across a wide range of site environments.

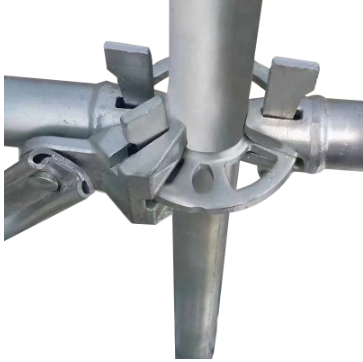

The cuplock scaffolding system is a multi-purpose steel scaffolding system built around a simple and strong node-point connection. The upper cup rotates to secure the blades of horizontal components, creating a rigid joint without requiring bolts or loose fittings. This allows workers to erect and dismantle scaffolding up to 30–40% faster than traditional tube-and-coupler methods.

The cuplock mechanism consists of two key parts:

Bottom cup (fixed to the vertical standard)

Top cup (sliding, used to lock components)

Ledgers and other components have forged blades at their ends. When placed into the bottom cup and secured with the top cup, the system forms a strong, load-bearing connection. This design eliminates the need for couplers and significantly reduces assembly errors.

The result is a highly standardized system with fewer components, faster installation, and dependable strength suitable for high-load structures and complex construction needs.

Below is a structured overview table summarizing major components.

| Component | Function | Features |

|---|---|---|

| Vertical Standards | Primary load-bearing member | Equipped with bottom & top cups |

| Horizontal Ledgers | Provide lateral support | Forged blade ends fit into cups |

| Diagonal Braces | Enhance stability | Prevent sway & improve rigidity |

| Base Jacks | Adjust height & level the structure | Support foundation of the system |

| Cantilever Brackets | Create extended platforms | Useful in façade and bridge works |

| Toe Boards | Fall protection | Installed along working platforms |

Each component is engineered for quick assembly, long service life, and consistent structural strength.

The cup-and-blade locking mechanism achieves rapid installation without nuts or bolts. Labor hours are significantly reduced, resulting in lower on-site construction costs.

The welded cups on vertical standards create a strong and stable connection. Cuplock scaffolding systems offer excellent compression resistance, making them ideal for formwork shoring and heavy-duty industrial applications.

Cuplock scaffolding is suitable for:

Building façade scaffolding

Access towers

Bridge and tunnel formwork

Industrial maintenance platforms

Heavy-duty shoring systems

Curved or irregular structures

This flexibility enhances project efficiency across different construction sectors.

Built from high-strength steel and protected with galvanization or anti-rust coating, cuplock components deliver long-term reliability, even under harsh construction environments.

The standardized design eliminates the need for couplers and reduces the number of different parts on site. Project management becomes easier, with lower maintenance and storage demands.

Across both developing and developed markets, cuplock scaffolding systems are preferred because they offer a combination of safety, speed, flexibility, and durability. Modern construction projects demand faster project cycles and higher productivity. Cuplock systems meet these expectations through:

Reliable structural performance

High adaptability to complex structures

Compatibility with various formwork systems

Reduced human error during assembly

Universal interchangeability of components

Thus, cuplock scaffolding continues to dominate global infrastructure, industrial, petrochemical, transportation, and residential construction sectors.

Cuplock scaffolding systems are commonly used for external façade scaffolding due to their high stability and fast erection. They provide safe working platforms for bricklaying, plastering, painting, and façade installation.

In bridge construction, the cuplock system is used to build heavy-duty shoring towers and formwork support platforms. Its high load capacity ensures safe and efficient concrete pouring.

Power stations, oil refineries, and chemical plants often use cuplock scaffolding systems as maintenance access scaffolding because the system can be adapted to complex pipework and irregular surfaces.

The system is widely used to support tunnel lining formwork due to its superior stability under compression.

Cuplock scaffolding offers safe platforms for high-rise façade installation, window fixing, and external wall operations.

The strength of a cuplock scaffolding system comes from its node-point design. When the top cup is tightened over the blades of ledgers, a rigid joint is formed. This connection:

Distributes loads evenly

Prevents dislocation of horizontal components

Increases structural stiffness

Enhances shock resistance

The rigid joints also reduce vibrations, making cuplock scaffolding suitable for dynamic construction environments and heavy machinery operations.

Below is a second comparison table that helps readers understand why cuplock remains a preferred choice.

| Scaffolding Type | Connection Method | Strength | Speed | Main Advantage |

|---|---|---|---|---|

| Cuplock Scaffolding System | Cup-and-blade | High | Very fast | Ideal for heavy-duty works & formwork support |

| Ringlock Scaffolding | Rosette locking | Very high | Fast | More flexibility & multi-angle connections |

| Tube and Coupler Scaffolding | Clamps & fittings | Medium | Slow | Highly adaptable but labor-intensive |

| Kwikstage Scaffolding | Wedge locking | High | Fast | Good for façade works & access scaffolding |

This comparison clearly shows that the cuplock scaffolding system offers a strong balance of speed, strength, safety, and cost-efficiency.

Safety is a critical requirement in any scaffolding system. Cuplock scaffolding provides:

Once ledgers are inserted and locked through the cup mechanism, they cannot be easily dislodged by movement or vibration.

Platforms can be configured with toe boards and guardrails, reducing fall hazards.

The vertical standards transfer loads effectively through their welded cups, ensuring strong load paths.

No bolts, nuts, or small parts means fewer chances for incorrect installation.

Such as safety nets, protective rails, staircases, and ladders.

Cuplock scaffolding is trusted by contractors for high-end infrastructure and industrial projects, including:

High-rise commercial towers

Large theaters and stadiums

Rail transit stations

Bridge and viaduct construction

Logistics centers and warehouses

Oil & gas processing facilities

Its ability to support heavy loads and adapt to changing designs makes it a preferred choice for both contractors and engineering firms.

Cuplock scaffolding components are typically made from:

High-strength Q235 or Q345 steel

Hot-dip galvanization

Powder coating or painted finish

Full welding with robotic or automated processes

These ensure corrosion resistance, long lifespan, and stable structural performance.

Although the system is low-maintenance, periodic inspections ensure long-term safety:

Check for bent or cracked standards

Inspect weld integrity around cups

Ensure base jacks move smoothly

Remove rust or repaint damaged surfaces

Store components safely to prevent deformation

Well-maintained cuplock scaffolding systems can last more than 10–15 years, even with frequent use.

The cuplock scaffolding system remains one of the most trusted, adaptable, and efficient scaffolding system solutions in global construction. With its fast assembly, high load-bearing capacity, durable steel structure, and proven safety features, it continues to be widely used in infrastructure, high-rise buildings, industrial plants, bridges, commercial complexes, and specialized formwork support works. For contractors seeking reliability and long-term value, cuplock scaffolding is a robust and cost-effective choice.

1. What is a cuplock scaffolding system used for?

It is used for access scaffolding, shoring towers, formwork support, bridge construction, industrial maintenance, and façade works.

2. What makes cuplock scaffolding different from tube-and-coupler scaffolding?

Cuplock uses a cup-and-blade locking mechanism, allowing faster installation and greater structural strength with fewer components.

3. Is cuplock scaffolding suitable for heavy loads?

Yes. The system offers excellent load-bearing capacity and is widely used for heavy-duty formwork and bridge projects.

4. How long does cuplock scaffolding last?

With proper maintenance, components can last 10–15 years or more due to durable steel and hot-dip galvanized surface treatment.

5. Can cuplock scaffolding be combined with other scaffolding systems?

In most cases, yes. It can be integrated with platforms, ladders, safety rails, and sometimes certain modular systems if compatibility allows.