Please Choose Your Language

Tel: +86-131-8042-1118

E-mail:

E-mail:

26 Huanghai Road, Leting Economic Development Zone, Hebei Province, China

Views: 0 Author: Site Editor Publish Time: 2025-07-15 Origin: Site

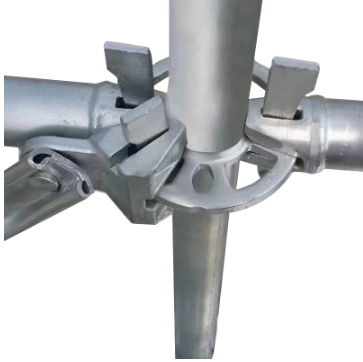

The installation of scaffolding systems is a critical aspect of any construction project. Among the many different scaffolding systems available, Ringlock scaffolding stands out due to its modular design, ease of use, and ability to provide stability in complex construction projects. However, the installation of Ringlock systems requires careful attention to detail. Even small mistakes during the installation process can lead to significant safety hazards, project delays, and costly repairs.

Proper installation is key to ensuring the safety and reliability of a scaffolding system. Ringlock scaffolding, which consists of vertical standards (poles) and horizontal components, offers great flexibility and support when correctly installed. However, any misalignment, improper locking, or failure to follow installation guidelines can lead to unstable structures that could collapse, endanger workers, and cause delays in the project.

When installing Ringlock scaffolding, it's crucial to adhere to all manufacturer specifications, guidelines, and safety standards. Let's dive into some of the common mistakes made during the installation of Ringlock standards and explore how these errors can be avoided to create a safe and stable scaffolding system.

One of the most common mistakes when installing Ringlock standards is failing to properly align the vertical and horizontal components of the scaffolding system. This misalignment can lead to an unstable structure, which may collapse under the weight of workers or equipment. Aligning the components ensures that the load is evenly distributed, preventing overloading in specific sections.

Use Alignment Tools: When installing the vertical standards and horizontal crossbars, always use levelers or a laser level to ensure everything is properly aligned. This will help in ensuring that both the vertical and horizontal components are straight and level.

Check Each Joint: Before tightening the connections, inspect each connection point to ensure the components fit perfectly. This minimizes the risk of instability or misalignment.

Follow the Manufacturer's Instructions: Adhering strictly to the manufacturer's guidelines will ensure that the scaffolding system is installed correctly, with the right alignments.

Another critical mistake made during the installation of Ringlock standards is insufficient locking of the connection points. The Ringlock system uses a wedge lock mechanism to connect the components. If these connection points are not locked properly, the scaffolding may be unstable, putting the entire structure at risk.

Confirm Complete Locking: Make sure that every connection point is fully locked before moving on to the next step. Use the wedge lock system correctly to ensure the components are securely fastened.

Use Inspection Tools: After completing the assembly, use a torque wrench or other inspection tools to verify that the connections are locked tightly. The locking mechanism should not move once it's in place.

Routine Maintenance: Regularly check the locking mechanism during the installation and after any movement or changes to the scaffolding. Over time, wear and tear can affect the lock's performance, so ensure it remains tight and secure throughout the project.

Some workers make the mistake of loading the scaffold too early or too heavily during the initial setup. This can result in the collapse of the structure, especially when the scaffolding is not fully secured. Scaffolding is designed to support specific loads, and exceeding these limits can compromise safety.

Follow Load Guidelines: Always consult the manufacturer's load guidelines before loading scaffolding. Adhere to the recommended load limits for each component and for the entire scaffolding system.

Gradual Loading: Do not load the scaffold all at once. Gradually add the load to ensure that the scaffolding is able to bear it properly. This approach allows you to detect any weaknesses or issues early on.

Weight Distribution: Pay attention to how the weight is distributed across the scaffold. Evenly distribute the load to prevent excess stress on specific parts of the system.

Using worn or damaged components can severely affect the stability and safety of the Ringlock scaffolding system. Components such as damaged standards, braces, or locks can compromise the entire system's integrity. It's essential to inspect each component before installation to ensure that no damaged parts are used.

Inspect Each Component: Before starting installation, inspect every component thoroughly for signs of wear, corrosion, or damage. If a component is damaged or shows signs of wear, replace it immediately.

Replace Damaged Parts Regularly: Set up a routine inspection and maintenance schedule to ensure that no part of the scaffolding system is compromised. Early detection and replacement of damaged parts can prevent accidents.

Quality Control Standards: Work with reputable suppliers and ensure that the components meet quality control standards. Always purchase scaffolding from reliable manufacturers like Huabei Yiande Scaffolding Manufacture Co., Ltd. who prioritize quality and durability in their products.

Installing scaffolding on uneven or unstable ground is one of the most dangerous mistakes that can be made during the installation of Ringlock standards. An unstable foundation increases the risk of collapse, especially when the scaffolding is loaded. Proper foundation preparation is essential to ensuring the safety and stability of the entire scaffolding structure.

Ensure a Stable Foundation: Before installing the scaffolding, ensure that the ground is level and firm. If necessary, add temporary supports or leveling devices to compensate for uneven ground.

Use Base Plates or Sole Boards: If the ground is particularly soft or uneven, use base plates or sole boards to distribute the weight of the scaffold evenly across the surface. This will help stabilize the structure.

Check for Ground Stability Regularly: Before and during installation, check the stability of the ground. Wet conditions, mud, or loose soil can cause the scaffolding to shift or sink, so ensure the surface remains solid throughout the project.

Safety should always be the number one priority during scaffolding installation. Ignoring safety protocols, such as proper personal protective equipment (PPE) or securing the work area, can lead to serious accidents.

Adhere to Safety Guidelines: Always follow safety protocols and guidelines, including wearing proper PPE (helmets, gloves, harnesses, etc.) and ensuring that the work area is clearly marked and restricted to authorized personnel only.

Conduct Safety Training: Ensure that all workers involved in the installation are properly trained in scaffolding safety. Regular safety briefings can help keep workers informed of best practices and potential hazards.

Use Safety Nets or Guardrails: In high-risk areas, consider installing safety nets or guardrails around the scaffolding to prevent falls and improve worker safety.

The proper installation of Ringlock standards is essential to the success of any construction project. By avoiding common mistakes such as improper alignment, insufficient locking, and overloading the scaffold, you can ensure that your scaffolding system is safe and stable. Regular inspections, adherence to load limits, and quality component checks are essential for a safe installation process.

When working on your next scaffolding project, be sure to follow these guidelines to avoid common installation mistakes. At Huabei Yiande Scaffolding Manufacture Co., Ltd., we are committed to providing high-quality scaffolding solutions designed to meet international standards. If you have any questions or need assistance with your next scaffolding project, don't hesitate to contact us. Our team of experts is here to support you every step of the way.

For more information or to inquire about our Ringlock scaffolding solutions, visit www.yiandescaffolding.com or contact us directly to discuss your needs. Ensuring safe and efficient scaffolding installations is our priority, and we're here to help make your projects a success.